Trusted Contract Broaching & Slotting Machine Suppliers Across North America

Precision keyway, spline cutting, and vertical slotting, powered by decades of experience and world-class broaching technology.

About Broaching Technologies

Precision Craftsmanship & World Class Customer Service

Broaching Technologies, LLC located in Menomonee Falls, WI offers a unique approach to contract broaching and broaching services. Whether your part requires a blind or through keyway, a spline or other specialized feature, we have experienced personnel with the expertise to deliver a cut above. And, we are advancing the industry with tooling options featuring a combination of standard tool set use and special tooling to complete the most demanding operations.

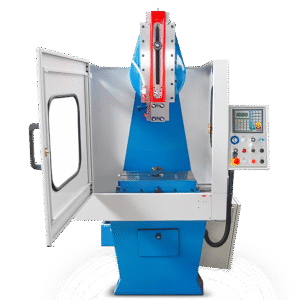

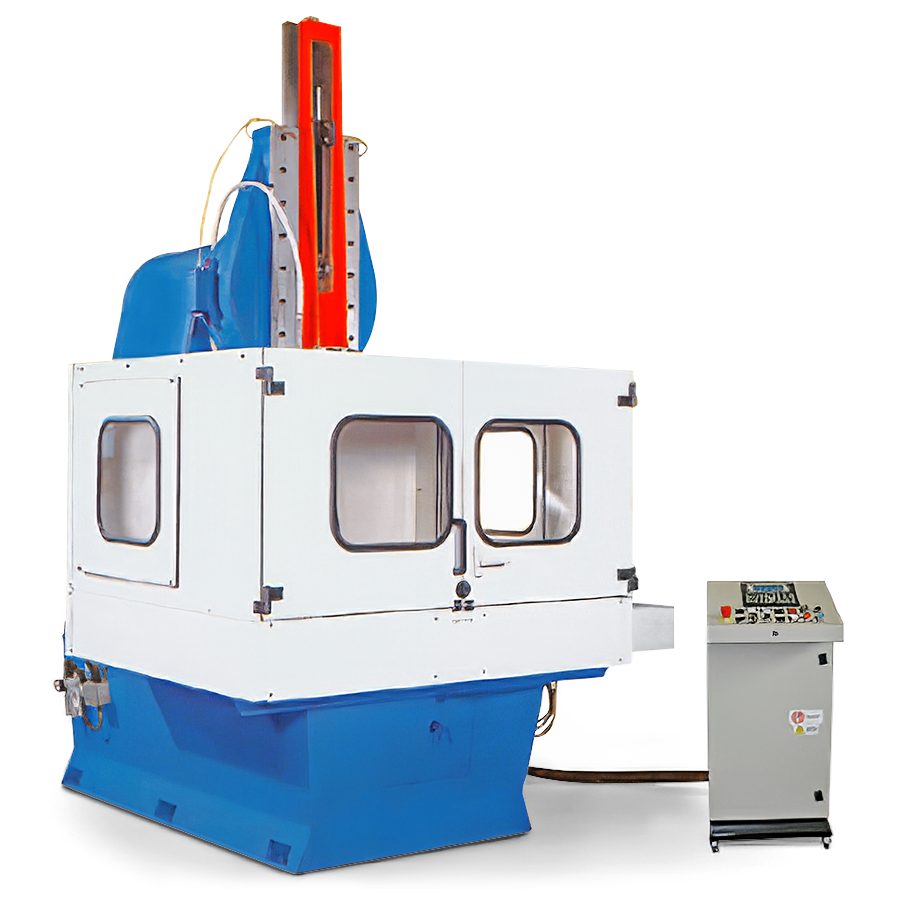

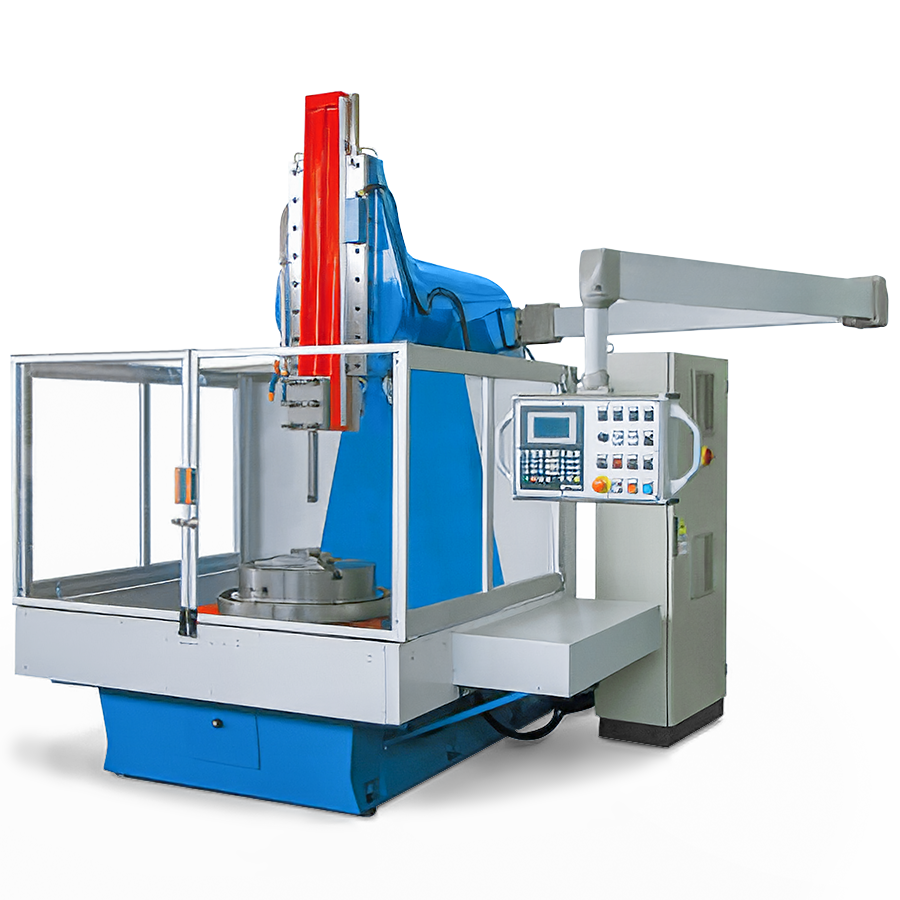

Exclusive North American Dealer for C.A.M.S Vertical Slotting Machines

C.A.M.S. is a premier Italian manufacturer that has excelled in the metalworking industry since 1975 and is recognized nationally and internationally for its design and production of high-performing, precision slotting machines.

Come See C.A.M.S. at IMTS 2026

September 14-19 – McCormick Place, Chicago

Visit Us at Booth # 237212

IMTS 2026 is where the creators, the builders, the sellers, and the drivers of manufacturing technology come to connect, be inspired, and find solutions. From around the globe, the industry gathers to discover the latest in innovations and technologies changing our future through advanced and traditional manufacturing, robotics, automation, and digital transformation. Be a part of the change.

Comprehensive Broaching & Slotting Solutions

From small runs to complex industrial parts, we offer high-tolerance machining services trusted by top manufacturers across sectors.

Keyway Broaching

Spline Broaching

Slotting Services

Internal Shape Cutting

Custom Broaching Jobs

Tooling & Setup Support

About C.A.M.S. Vertical Slotting Machines

Precision machining and operational flexibility are features incorporated in the C.A.M.S. Slotting Machines and the result of years of technical expertise and experience in this market combined with valid suggestions on improvement from some of our most demanding customers. Broaching Technologies’ entire range of Slotting Machines come supplied with electronic tool lift and feed; and it is possible to select models with 1,2,3 or 4 NC-controlled axes to best satisfy your production requirements.

Heavy-Duty Industrial Performance

C.A.M.S. machines are built for longevity and repeatable performance, even in the most demanding production environments.

Versatile and Programmable

Options include one to four NC axes, electronic rotary tables, and programmable strokes to suit modern slotting needs.

Trusted by Top Manufacturers

These machines are trusted by global OEMs and precision part producers, ideal for clients seeking a reliable key broaching machine solution.